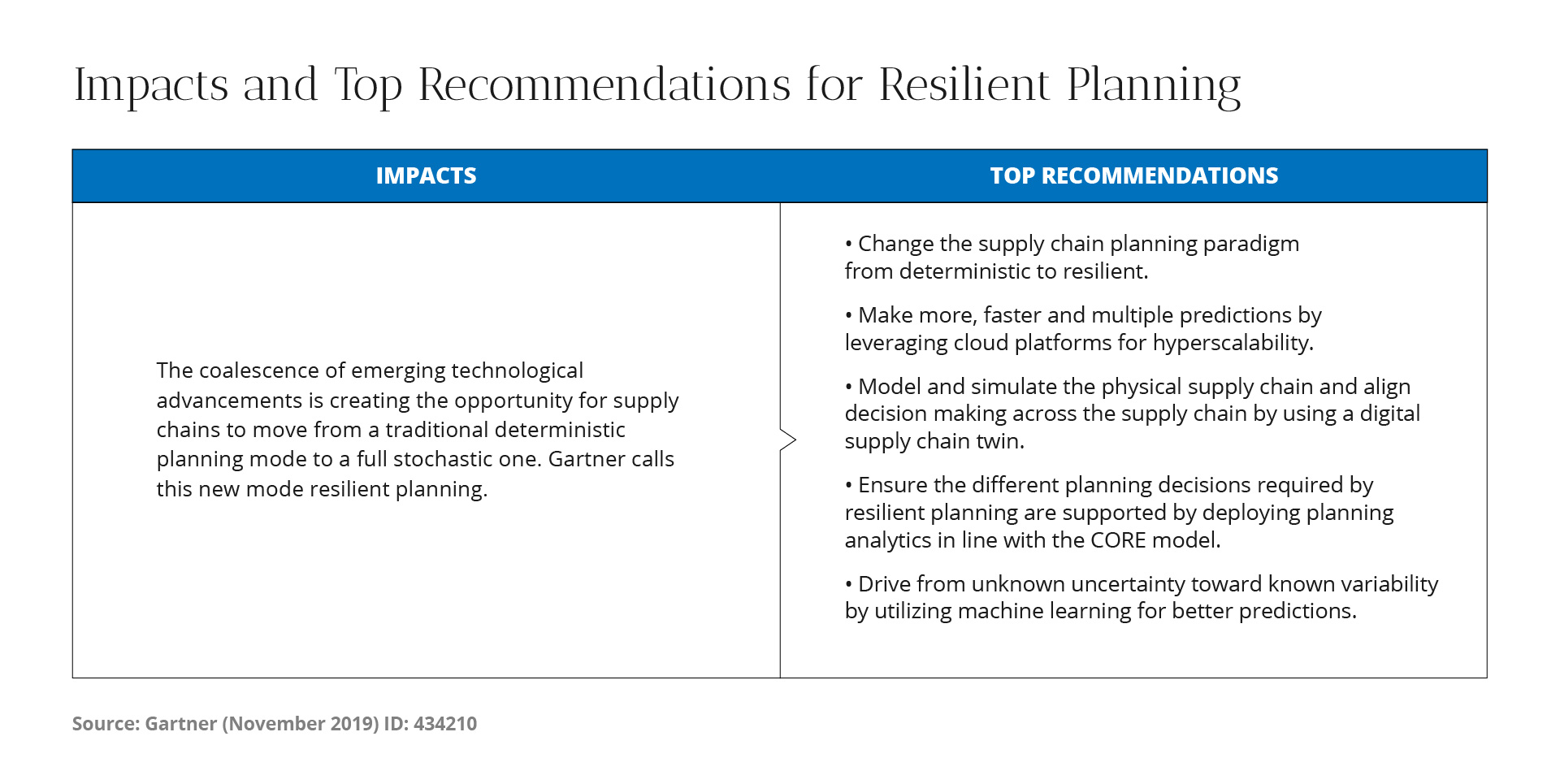

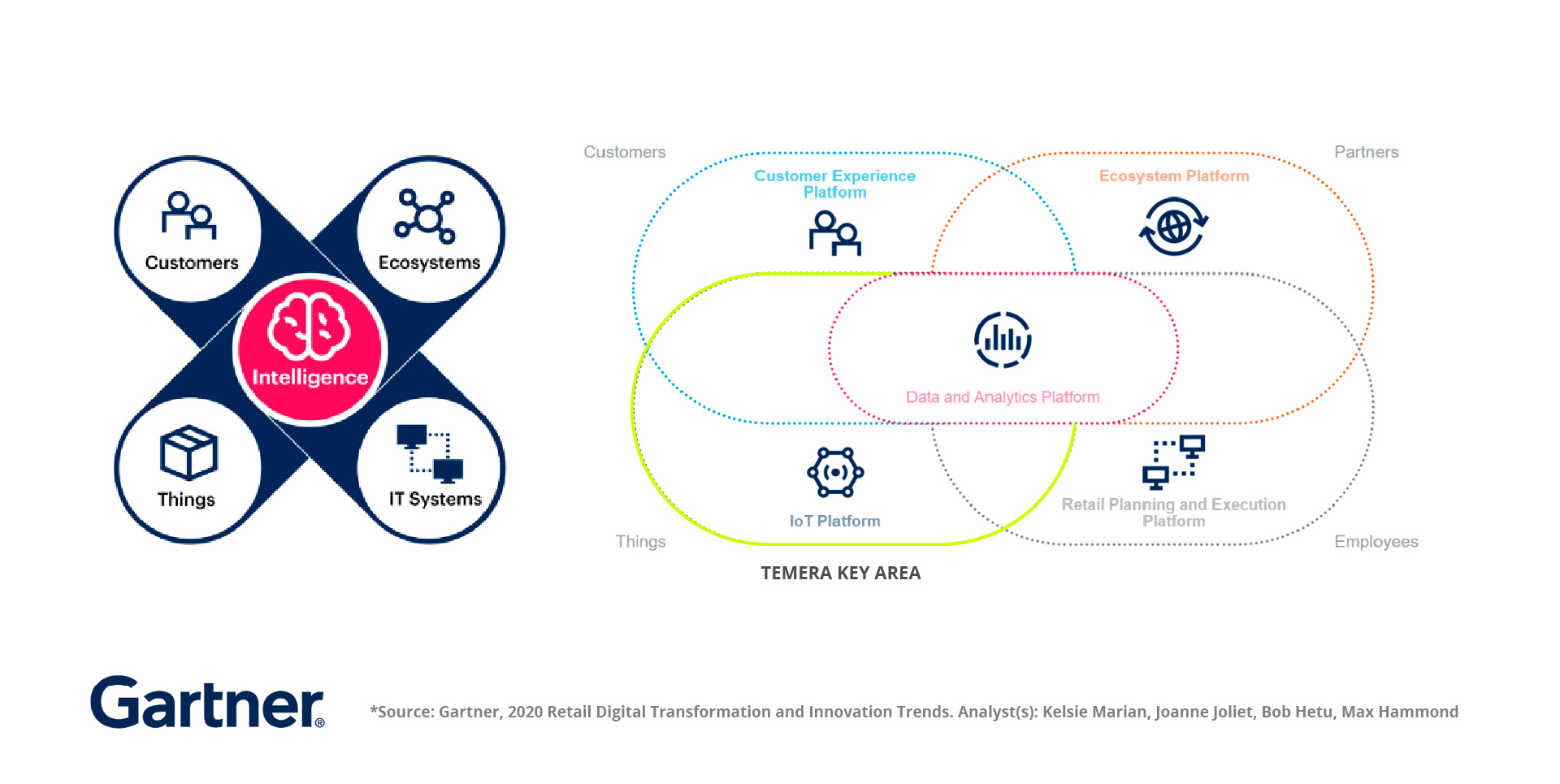

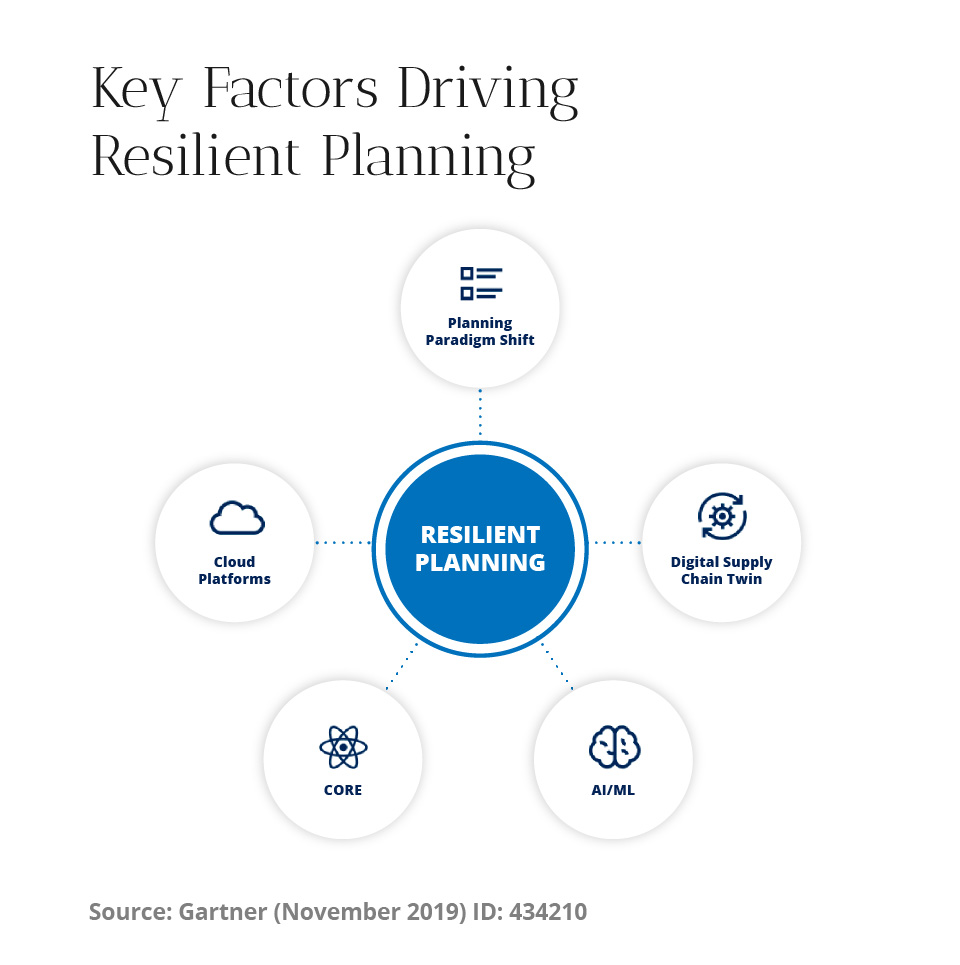

An advanced data analysis environment, equipped with a ‘data integration’ engine capable of bringing together information from heterogeneous systems, completes the set of tools necessary to be able to face a project aimed at reorganizing the supply chain following innovative resilience parameters.

Additional benefits come from the capability to exploit pre-trained Machine Learning models to convert unknown uncertainty into known variability.