Arcangelo D’Onofrio, CEO Temera

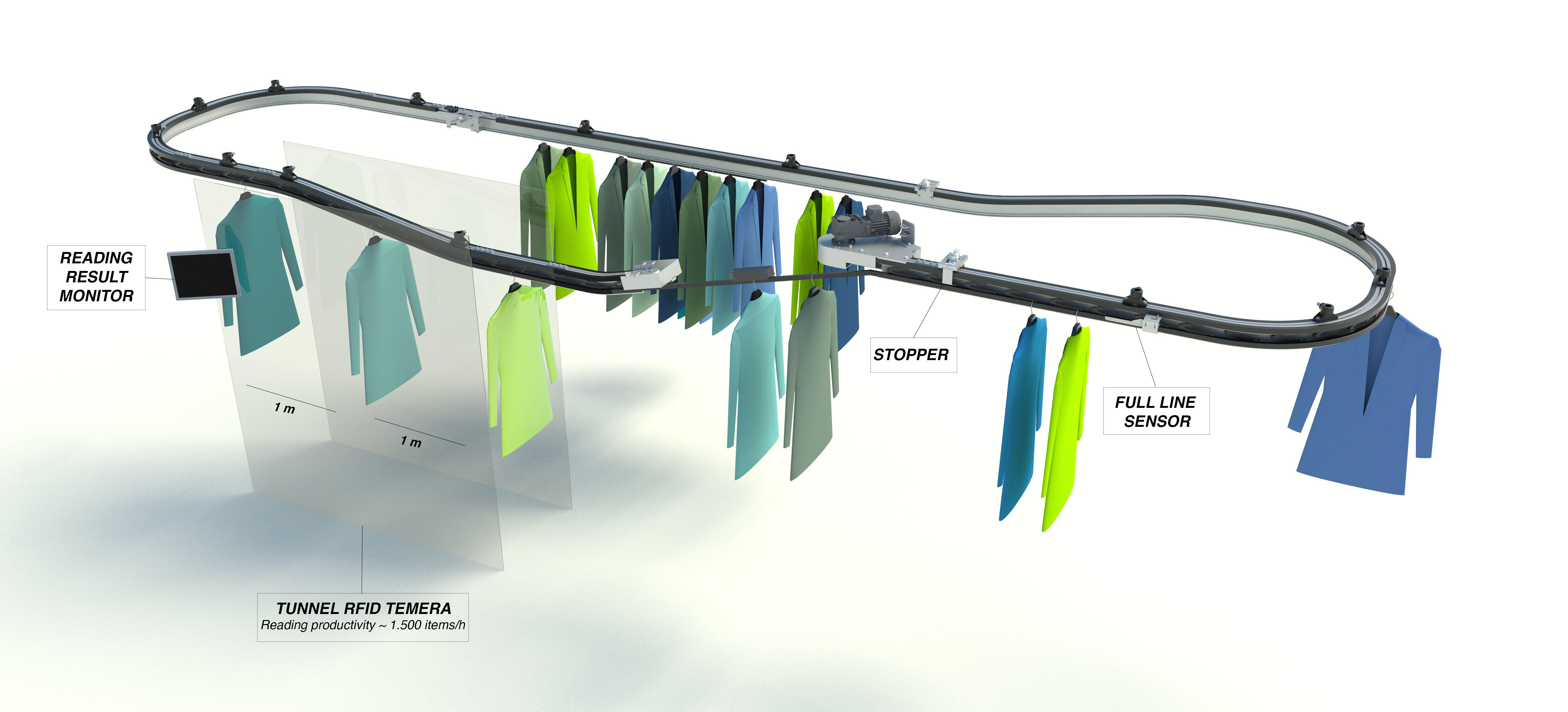

t!Conveyor

Temera and MHART announce their strategic partnership geared towards offering high-level automation solutions for logistics activities in the Fashion & Luxury sectorTwo premium, innovation-driven Italian companies combine their respective visions to develop logistical automation projects based on IoT sensor applications and on automated material-handling solutions.

The partnership seeks to promote the development of highly automated solutions for logistics applications through the use of RFID technology and single-garment conveyor lines, designed and manufactured by MHART. These are able to convey and sort the garments into a process where handling and traceability are integrated in a completely automated manner.

Through a series of automated components, the hanging garments are first counted and then checked for ID correctness with a RFID reading system: once the read data is compared against the expected data, the product is sorted either towards the operational areas or where it can be immediately checked if an anomaly is found in the specific product or job order.

Right from the outset, t!Conveyor is fully integrated with the Temera Stylewhere platform, the exclusive technological enabler capable of guiding the digital authentication of products and tracking them along the entire value chain.

A fully integrated and operational demo version of the solution is available at the MHART headquarters in Gessate (near Milan), where interested customers can test their garments on the system in both the hanging and the flat (into the hanging-bag units – bag sorter).

Arcangelo D’Onofrio, CEO Temera

The evolution of the fashion market has made integrated solutions the norm and customers demand projects that are already sized and configured for supporting them in their future business.

Andrea Di Bella, CEO di MHART