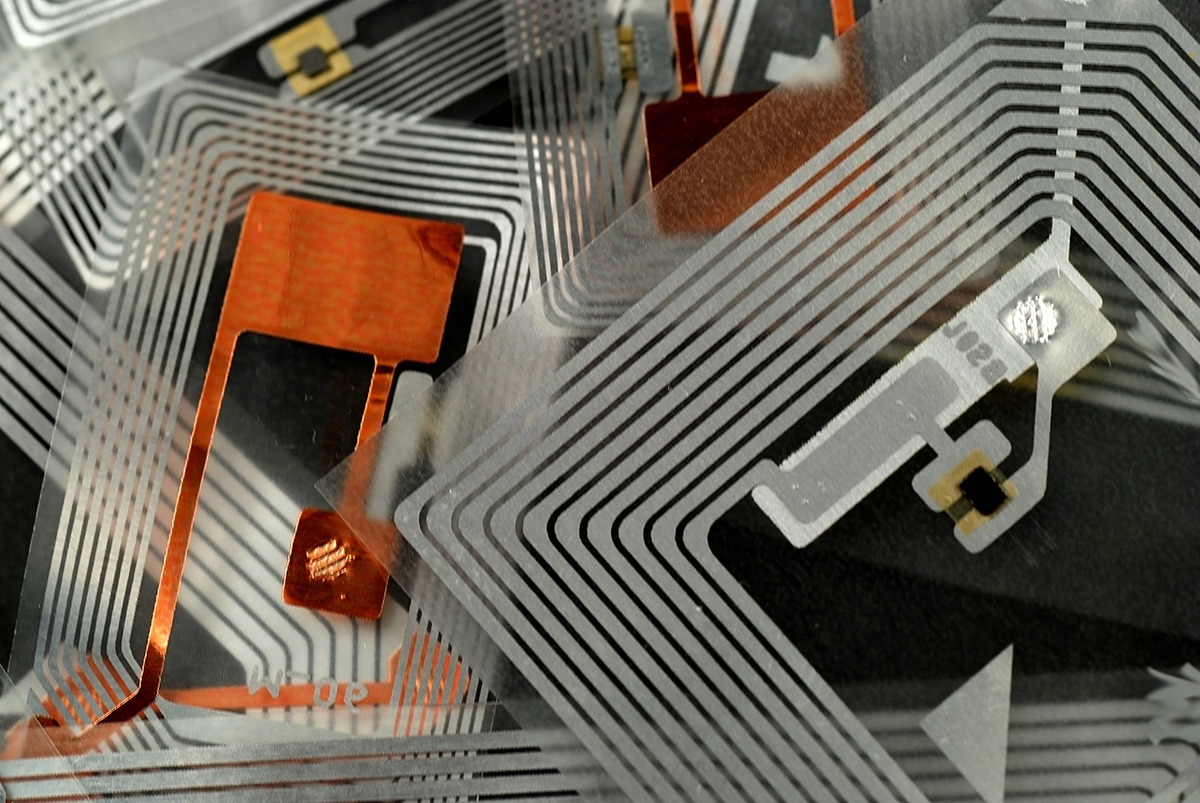

Two versions of the RFID system are available, namely UHF (Ultra High Frequency) and NFC (Near Field Communication).

The difference between the two systems, as their names suggest, lies in their differing coverage zones inside which the tags are readable. UHF allows coverage over several metres, proving accessible only to large industrial sectors such as logistics companies, whereas the latter is targeted at final consumers, owing to increasing numbers of NFC readers housed in smartphones and tablets.

Going back to two of the main markets targeted by the Made in Italy attack mentioned earlier, examples of an effective way of using RFID solutions can be found in the fashion sector, by inserting tags in clothing labels so as to complement existing anti-shoplifting systems, and in the food/beverage sector, by inserting tags in the corks of wine bottles so as to ensure traceability throughout the entire distribution channel.

Other areas where RFID technology is proving effective are logistics and freight transportation. In an industry where tracing all activities and monitoring the positioning of goods is essential, RFID enables geolocation of pallets in warehouses, minimising the risk of errors and boosting organisational efficiency.

RFID technology is an extremely attractive, versatile anti-counterfeiting, anti-tampering solution It adapts easily to the most diverse IT environments, making it ideal even for SMEs. It does not require major set-up or operational changes and, therefore, also guarantees very limited expenditure.

Its versatility is also due to the option of integrating the RFID system with other technologies that are available on the market. Let’s take a closer look at the various integrated solutions that may be implemented using an RFID.